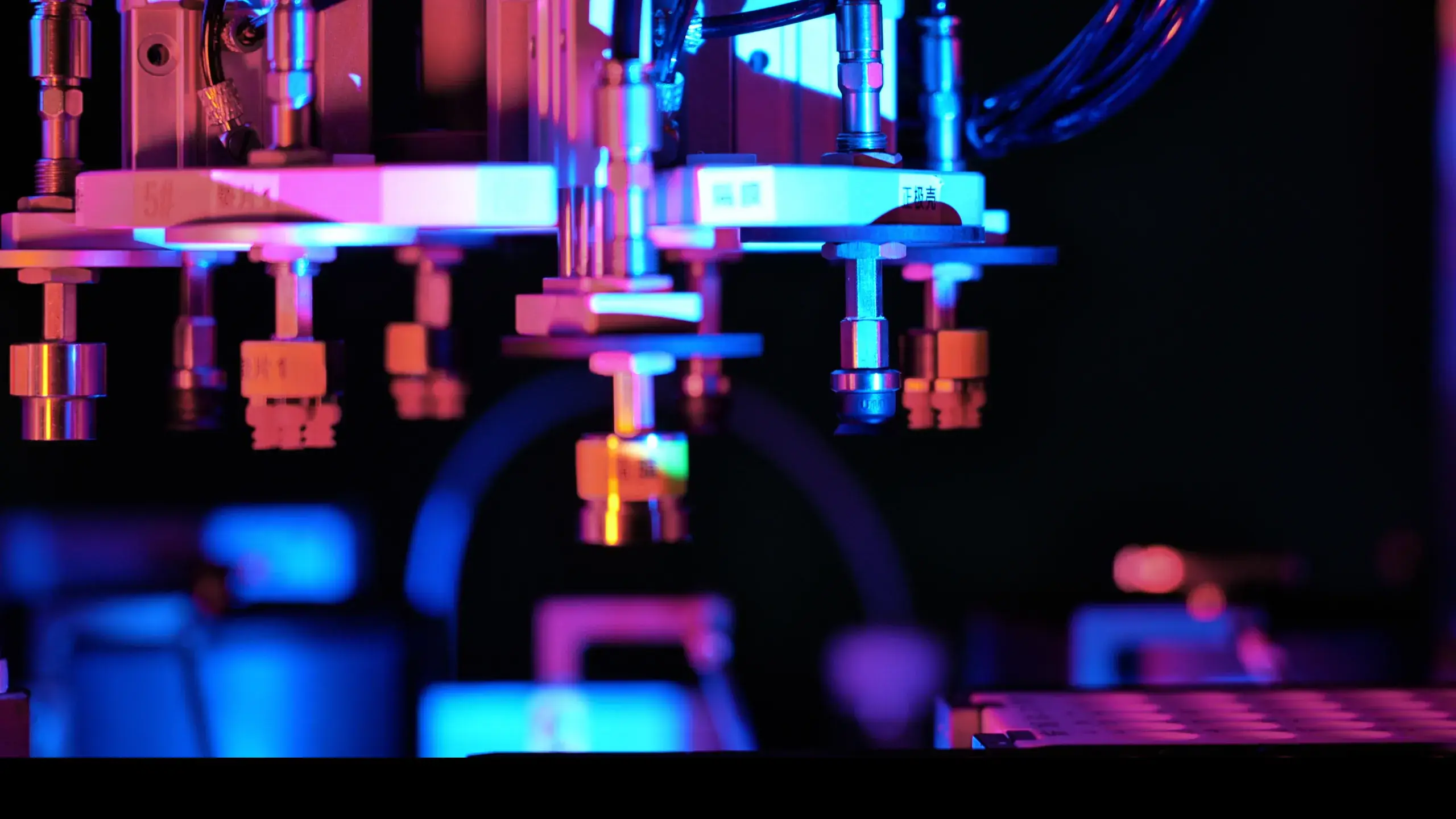

System Features

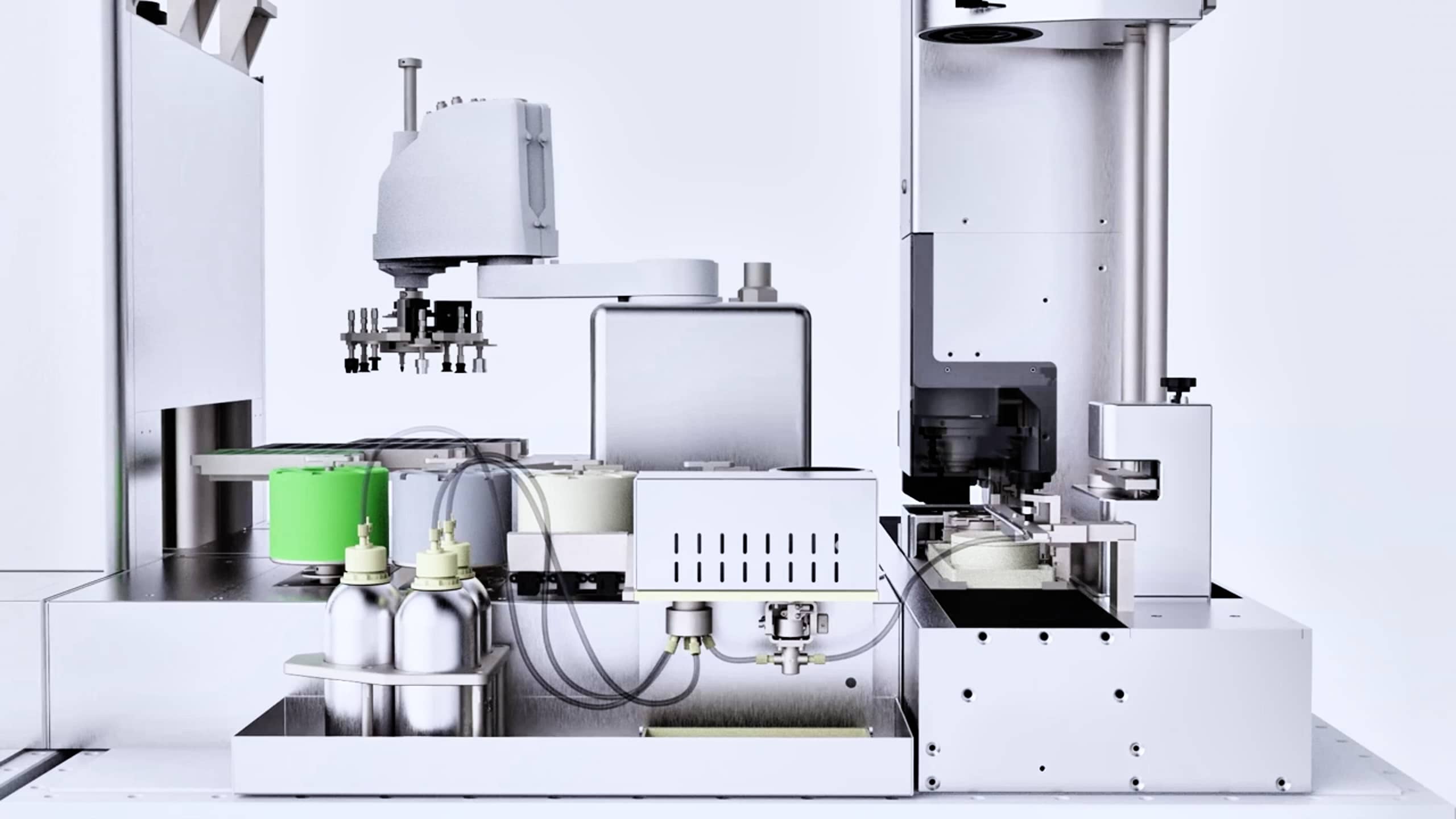

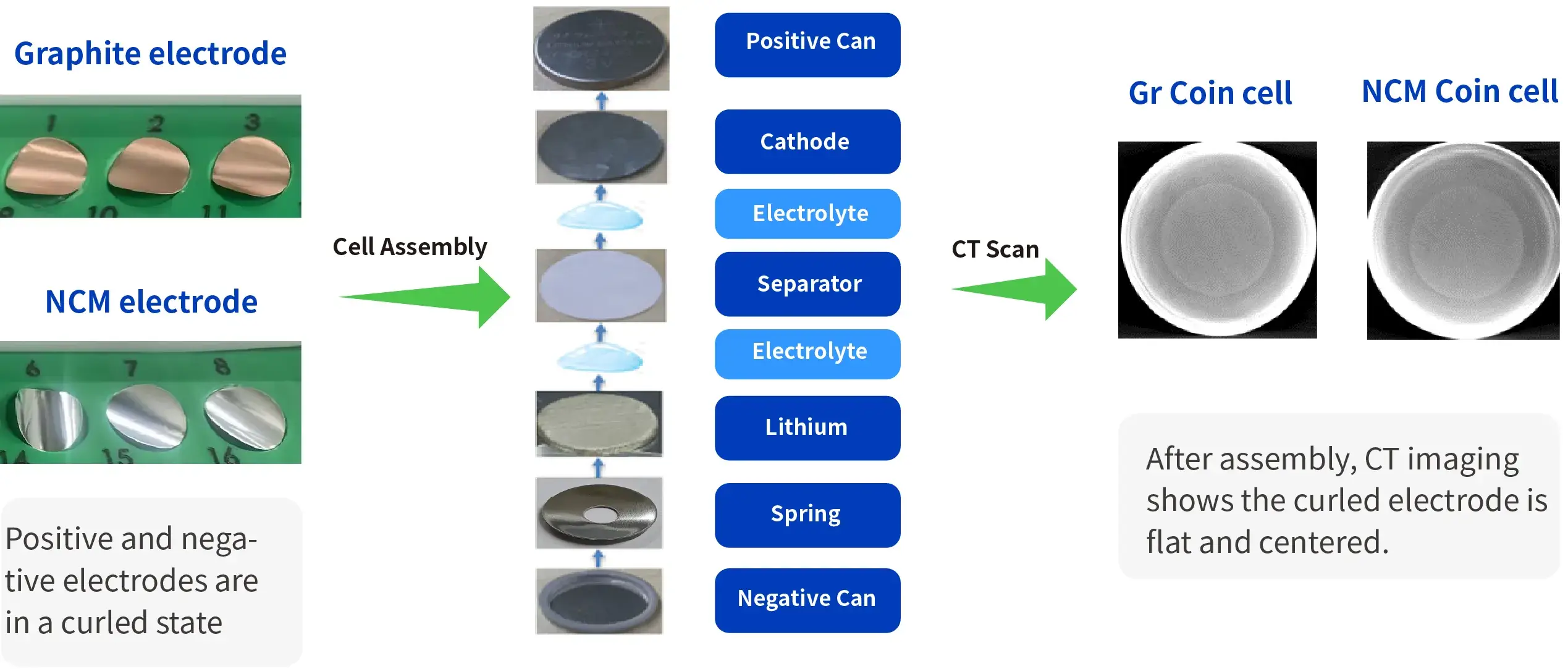

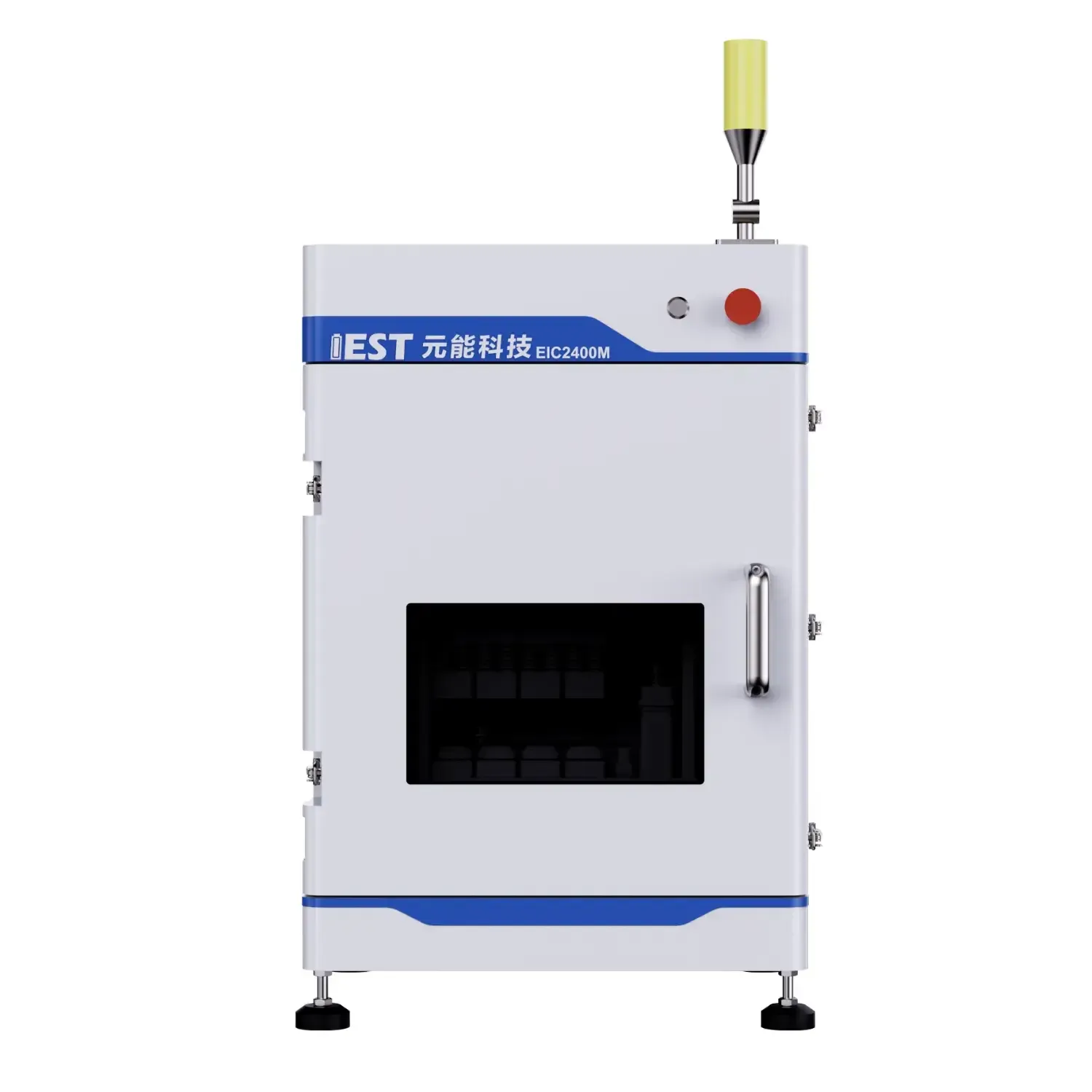

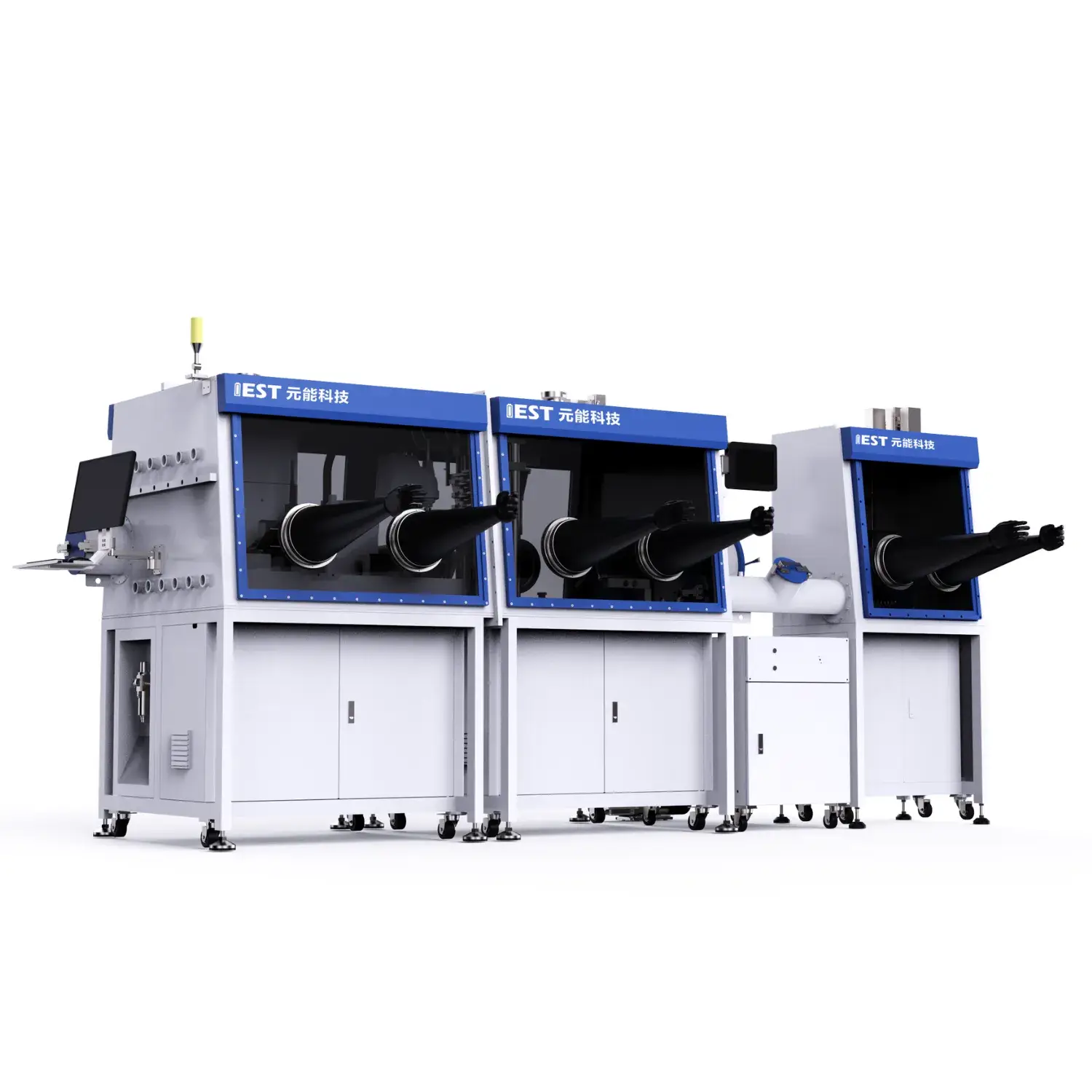

Glove Box Integration

Integrated glovebox provides controlled anhydrous/oxygen-free assembly atmosphere ensuring coin cell performance.

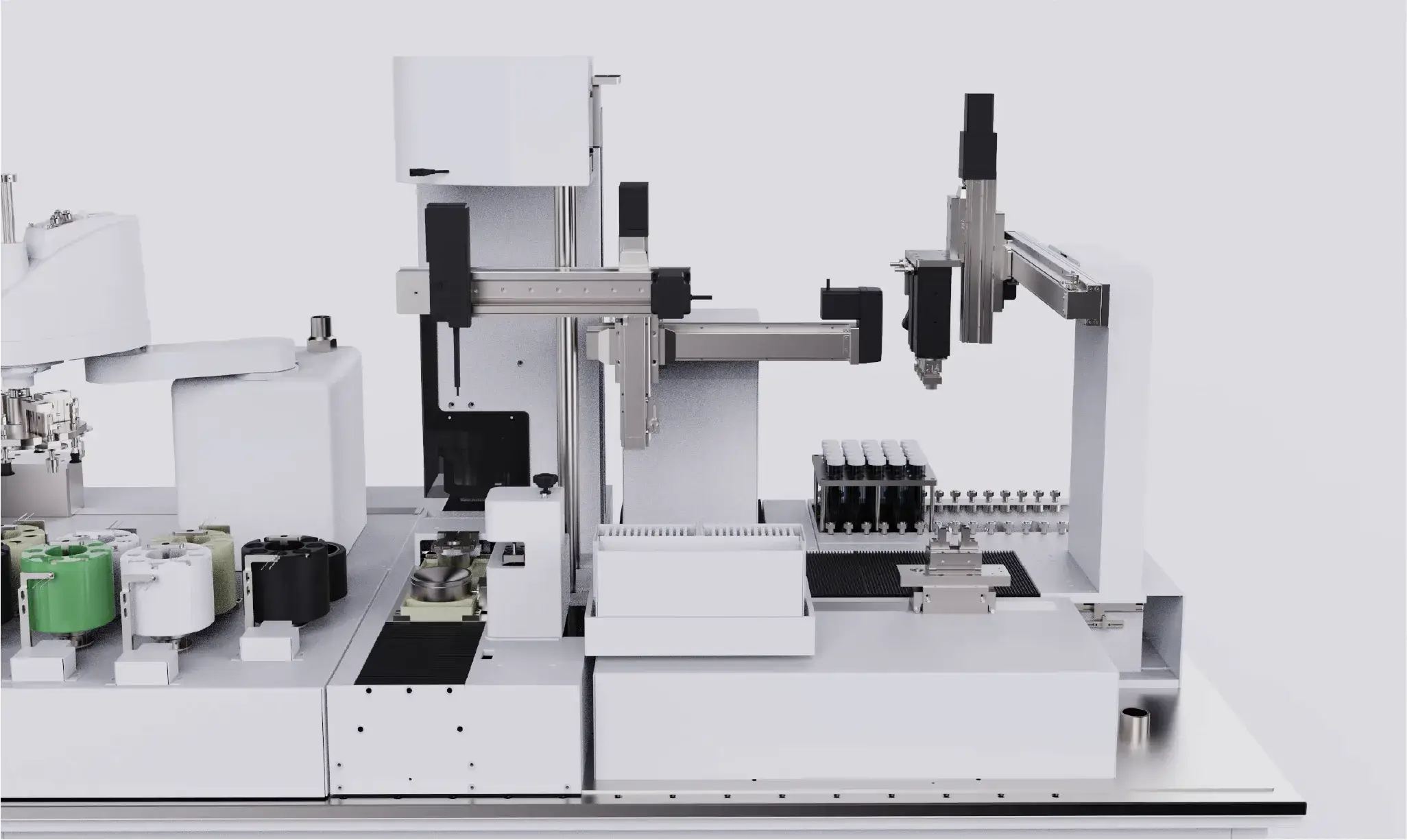

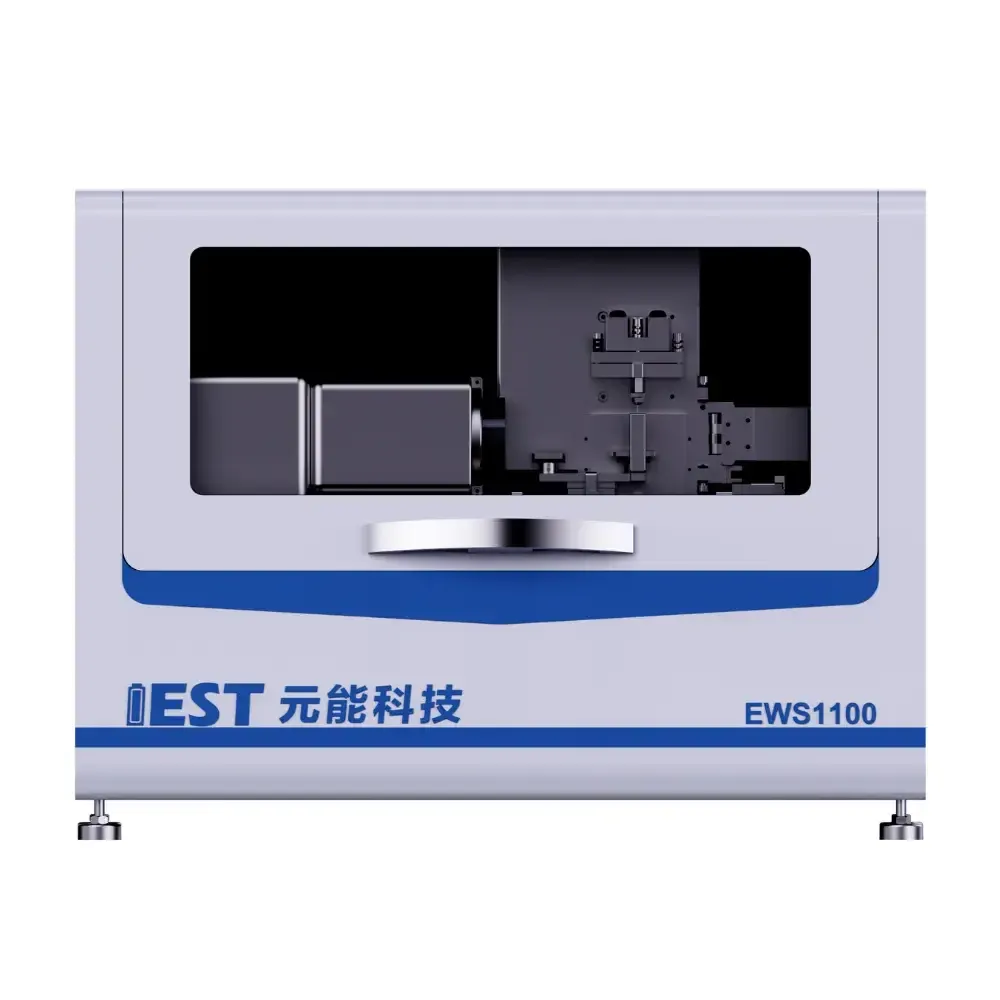

High-speed Robot Assembly

High-speed robotic material handling with optimized layout achieves ~1cell/min, enabling high-throughput coin cell assembly.

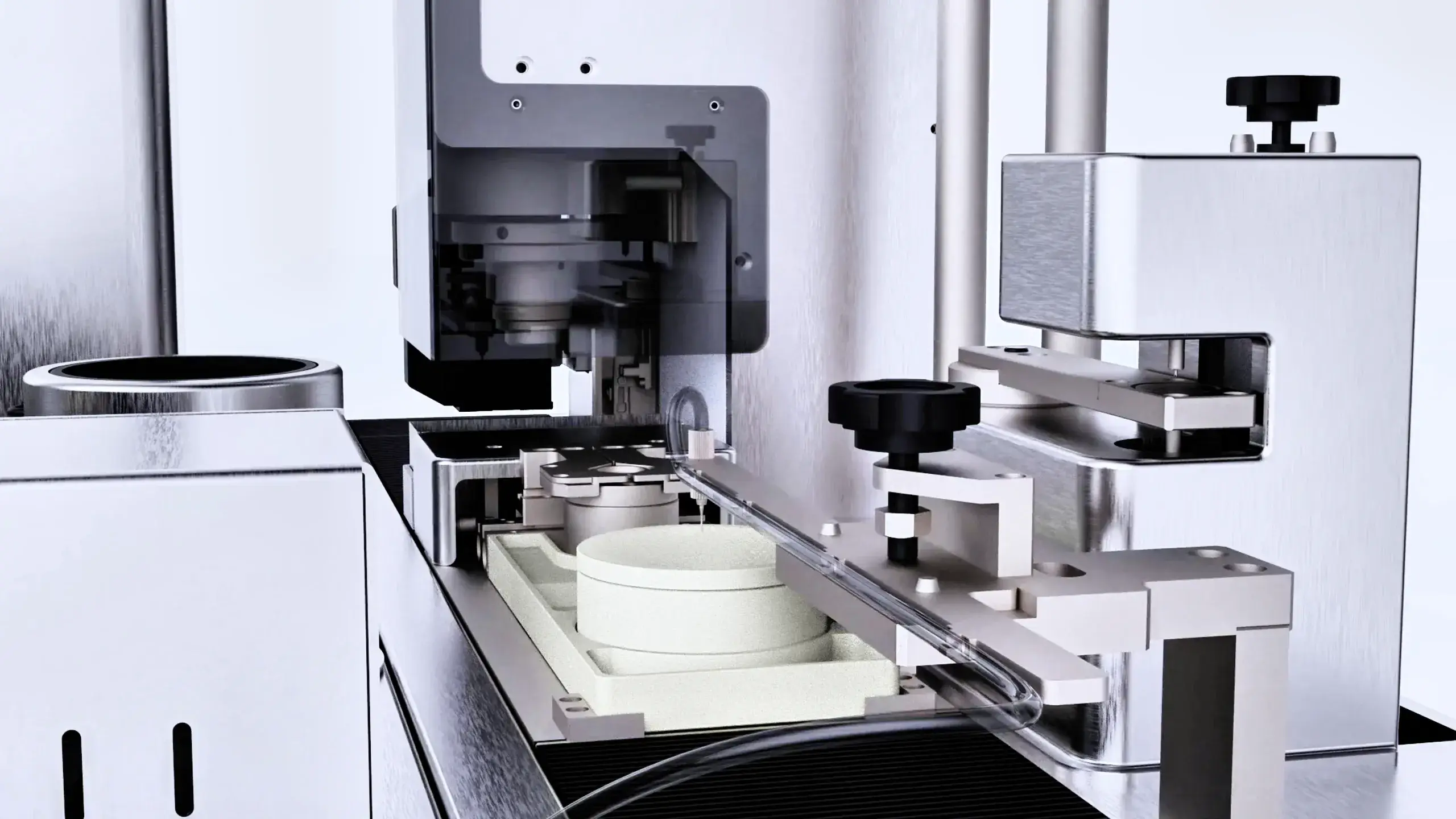

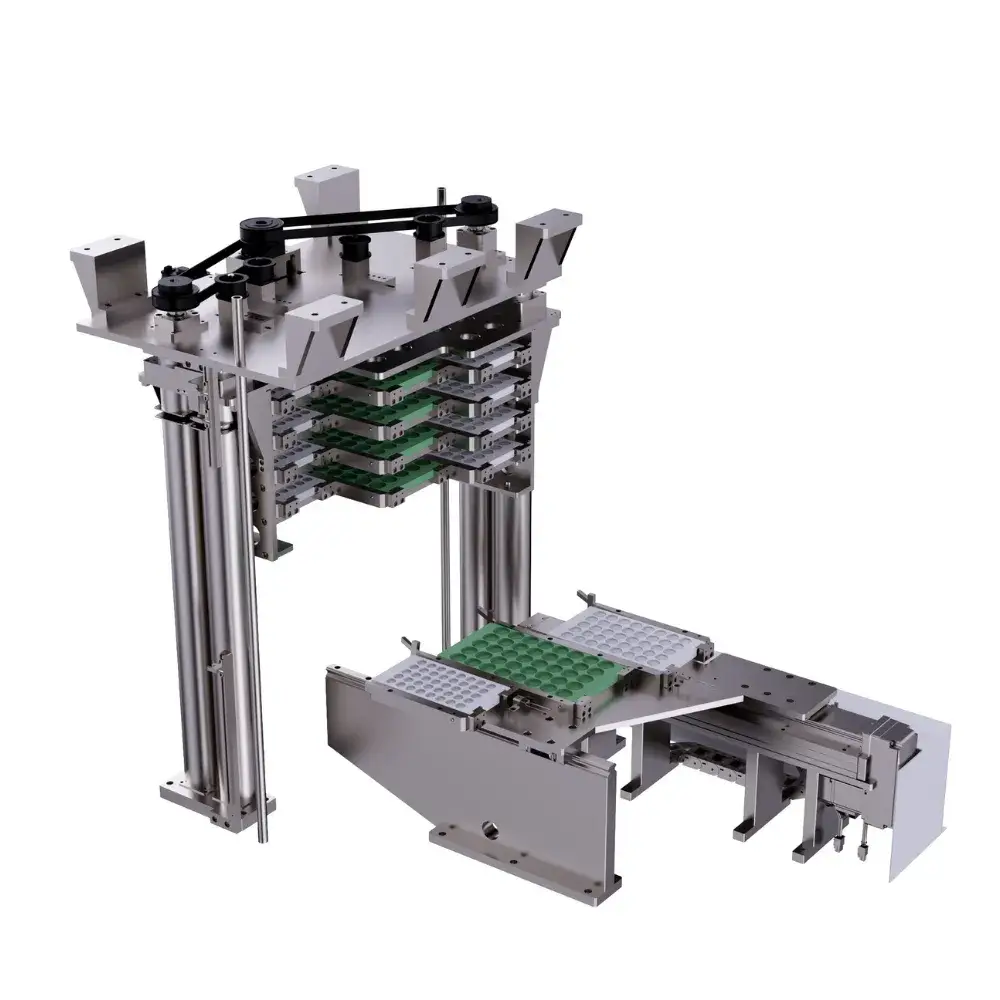

High-precision Assembly

±0.2mm concentricity tolerance guaranteed by precision positioning system for consistent coin cell stacking.

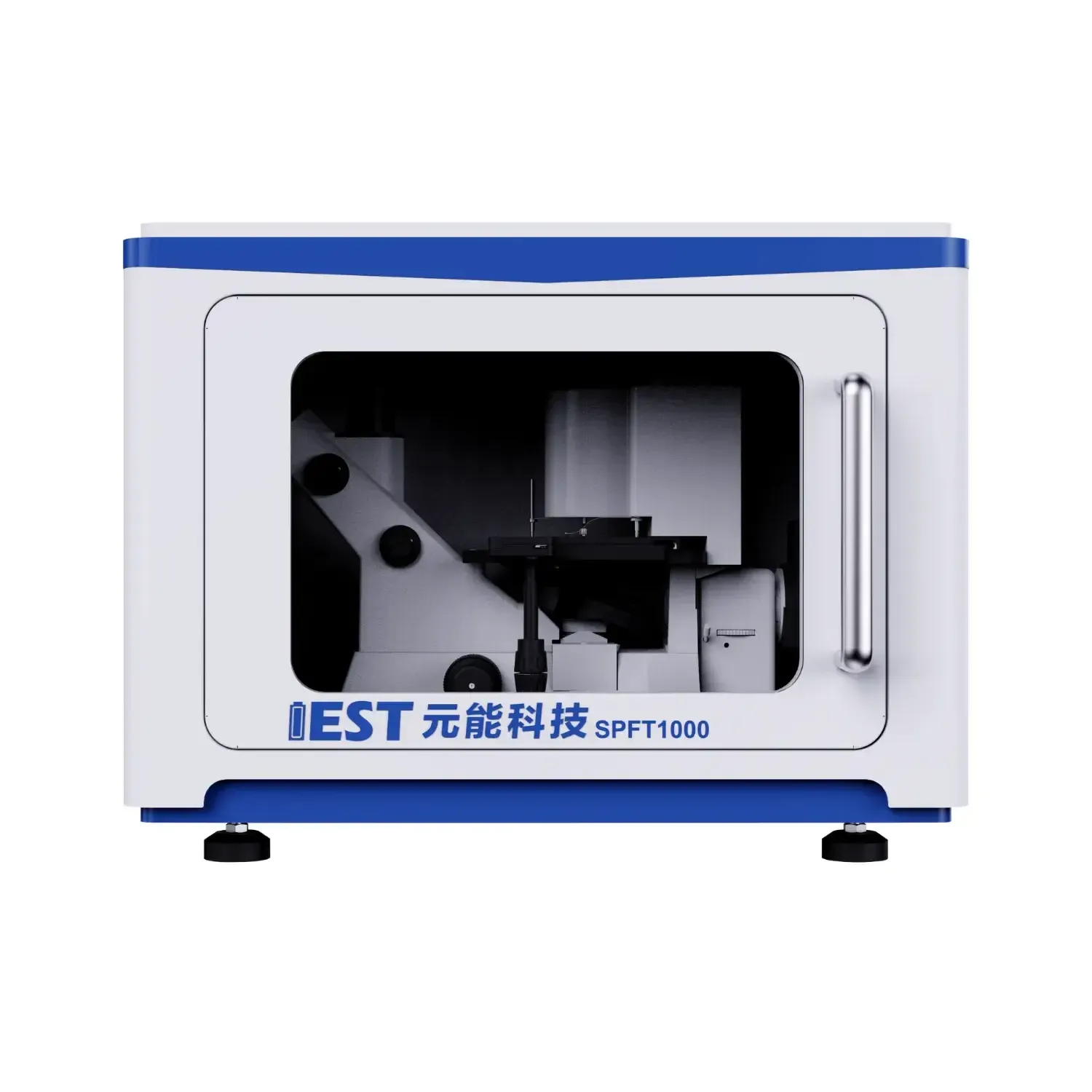

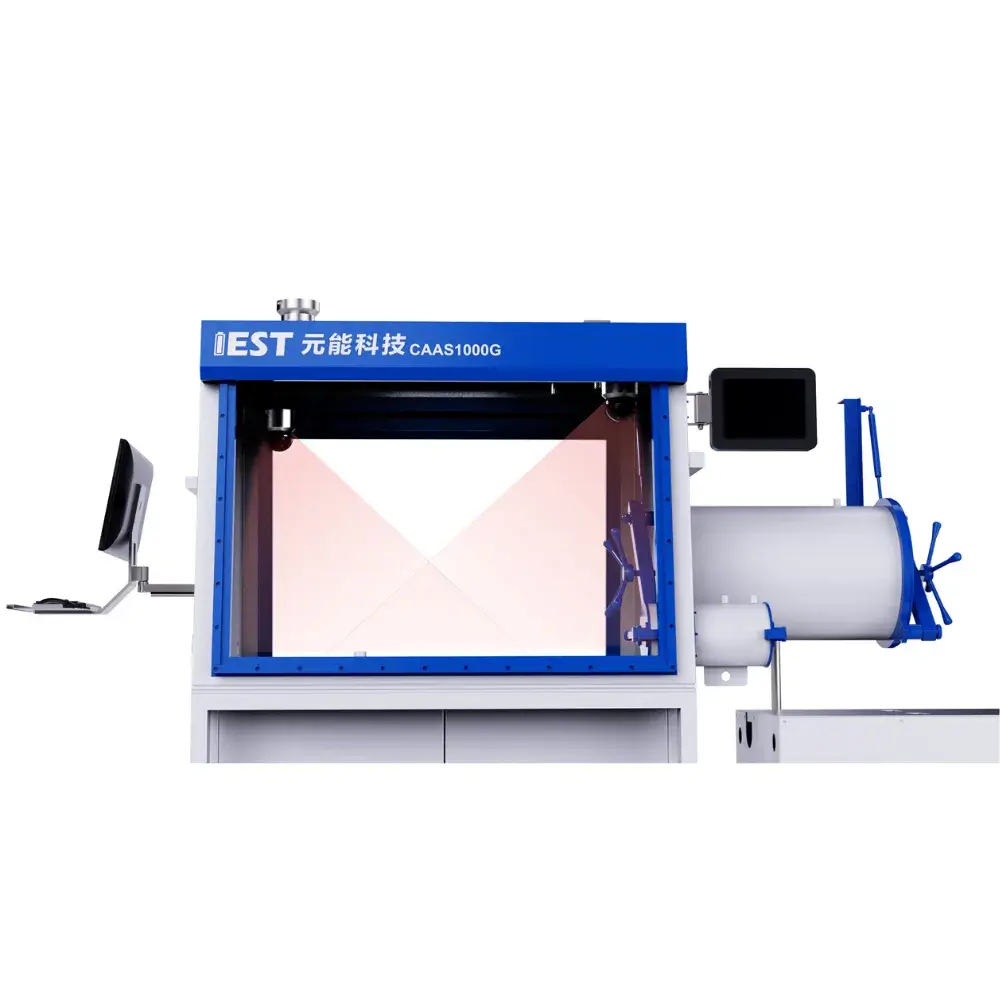

Cell Assembly Process Taceability

(Optional) Process traceability system with HD imaging and AI-based inspection for defect material rejection.

High-throughput Assembly

Batch loading capacity: 200 cells enabling continuous high-throughput assembly.

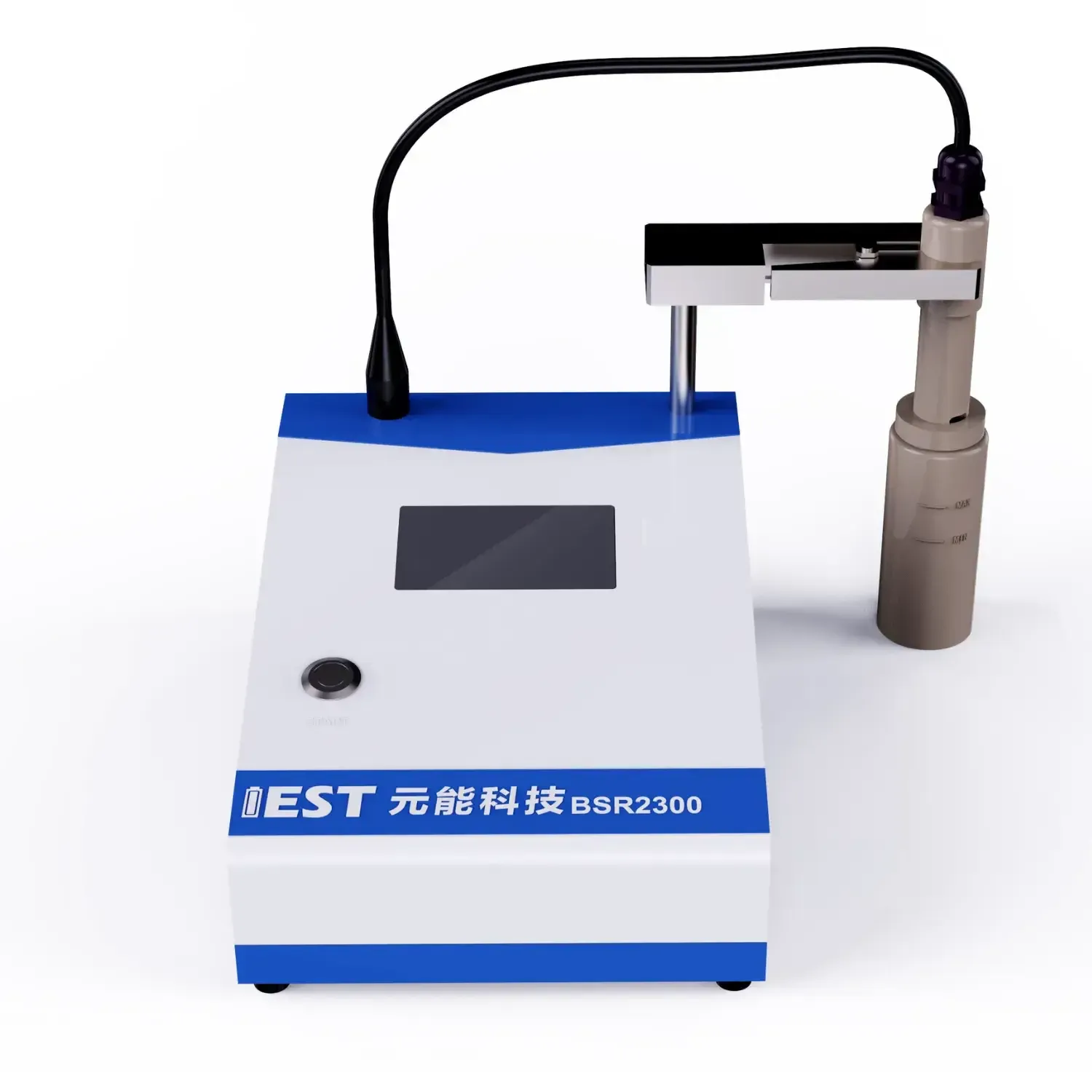

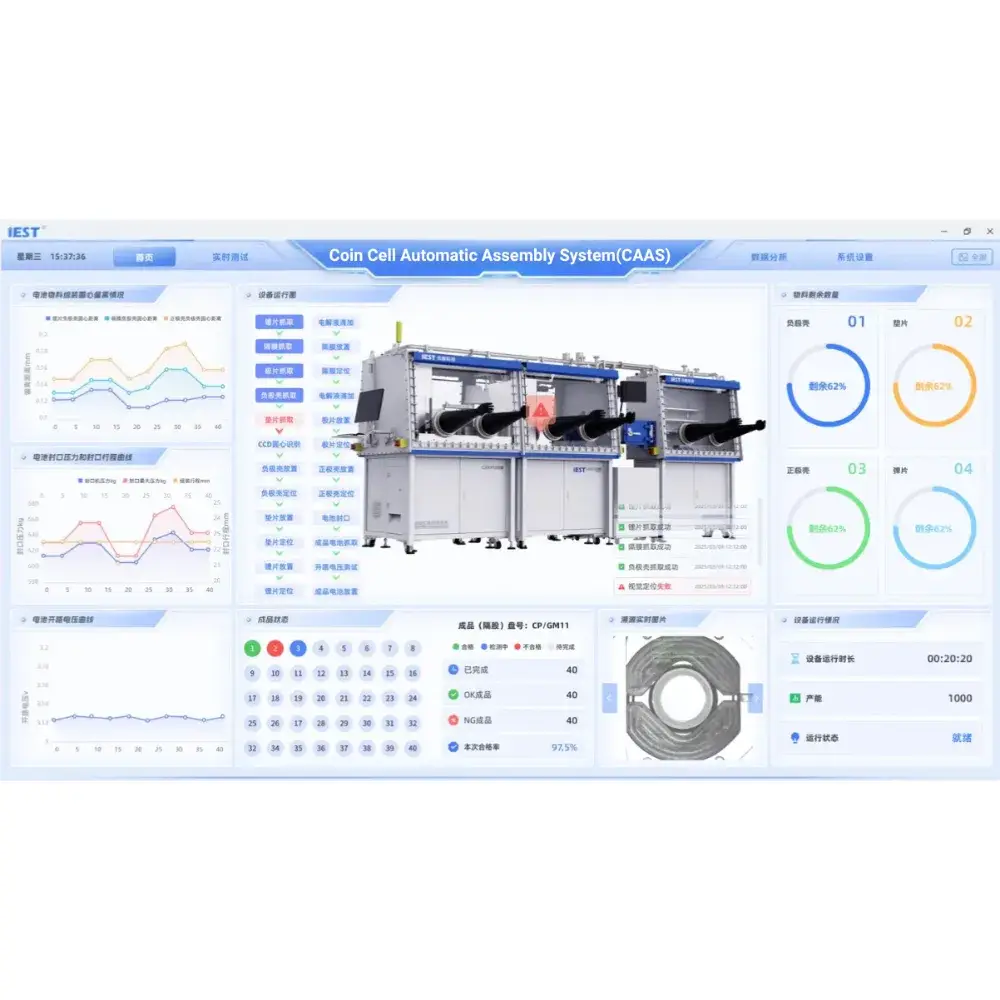

Batch Association

Electrode materials traceable via barcode scanning; In-chamber inkjet marking enables batch association.

Auto Electrolyte injection

Automated electrolyte injection with online switching between chemistries + inline system rinsing.

Online Voltage Test

Online OCV testing monitors cell survival rate and equipment stability.

Material Tray

Centralized feeding system: Electrode/separator/lithium foil trays with material traceability.

Automated Lithium Foil Brushing Function

(Optional) Automated lithium foil brushing module enhances surface quality and stacking uniformity.

Sentinel Management

Top-mounted diagonal HD cameras enable real-time process monitoring and management.

Functional Modularity

Modular architecture allows flexible configuration and providing customized services

Particle Control

Glove box with dedicated dust removal, cleanroom-grade 4-axis robots, shielded drive components, non-metallic trays with material-specific vacuum grippers.

Data Process Software

Proprietary data management software automatically aggregates process parameters for user-friendly access and archiving.