IEST Lab-sclae Automatic Coin Cell Assembly Machine(CAAS)

Next-Gen Coin Cell Assembly Machine For Lab-scale

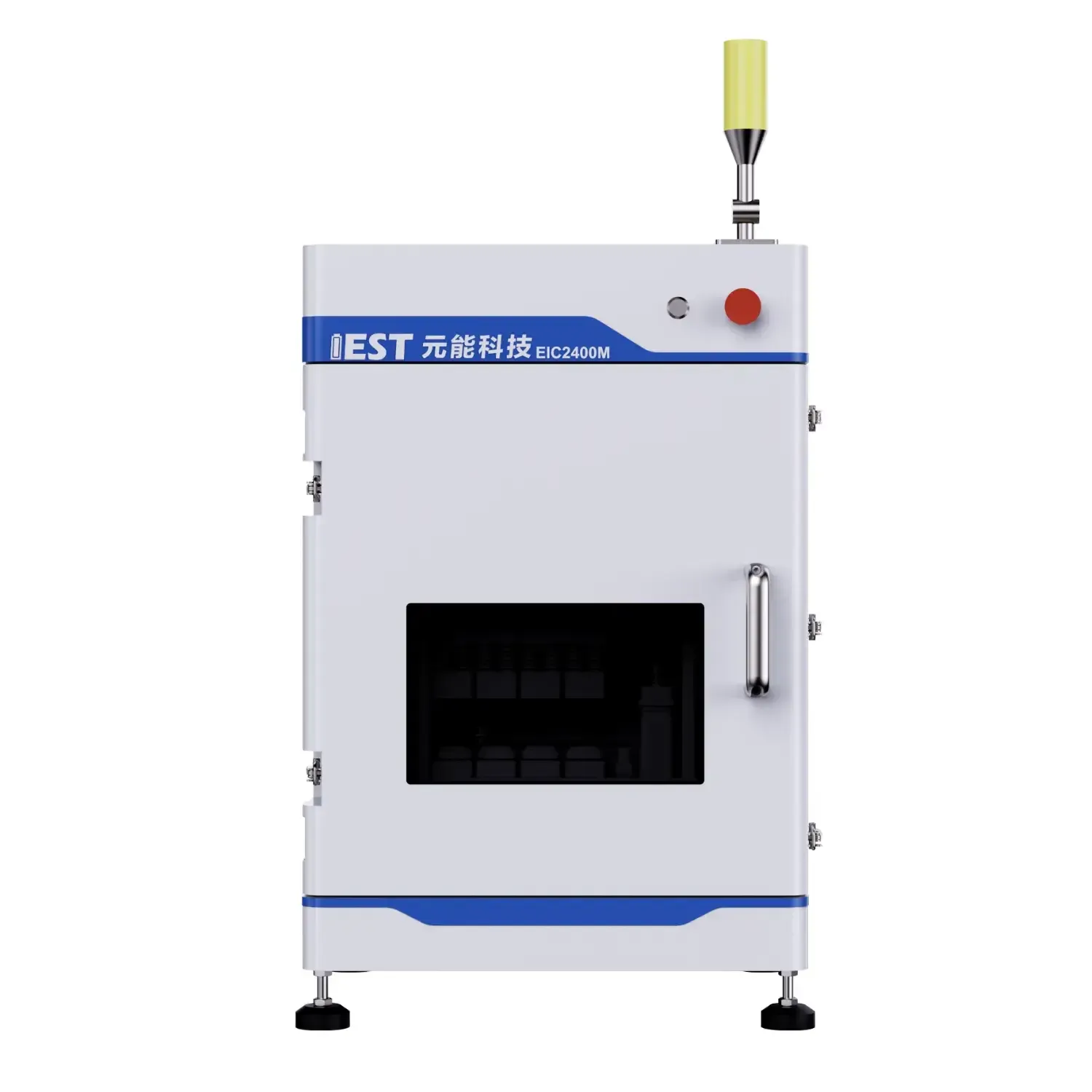

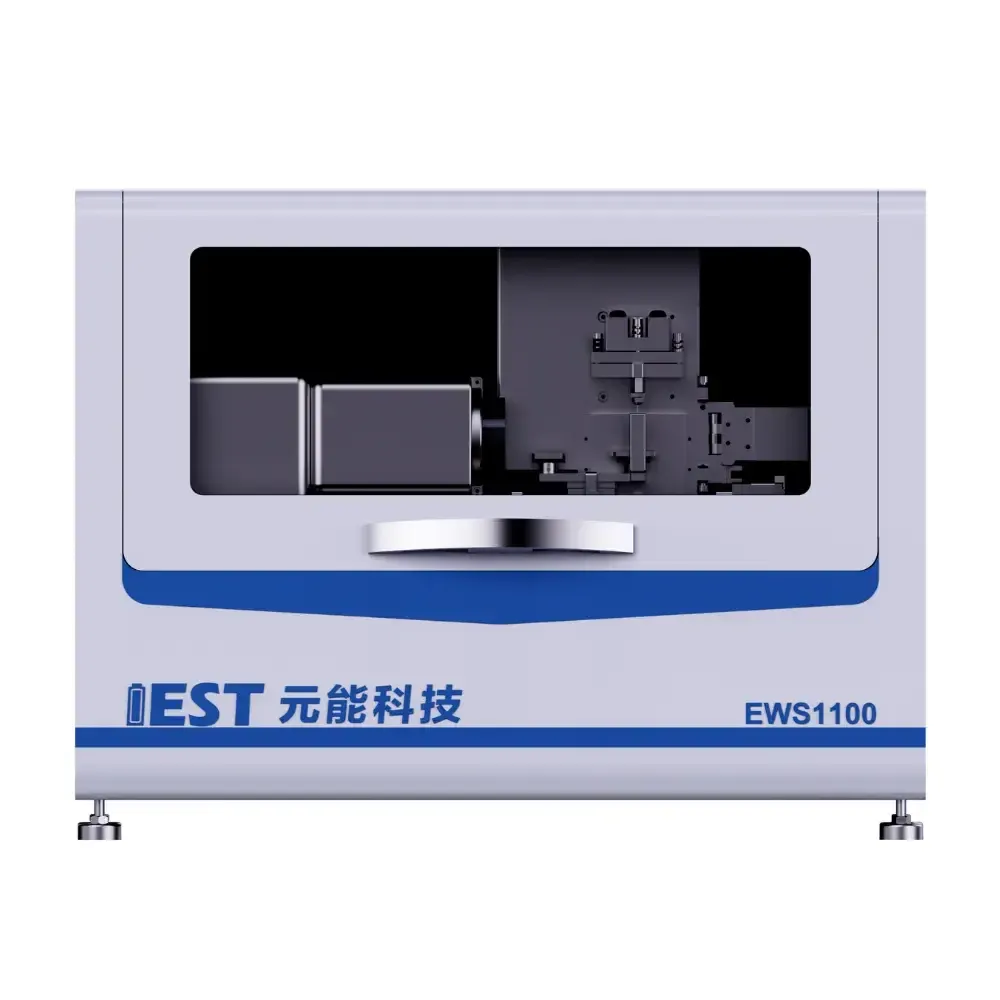

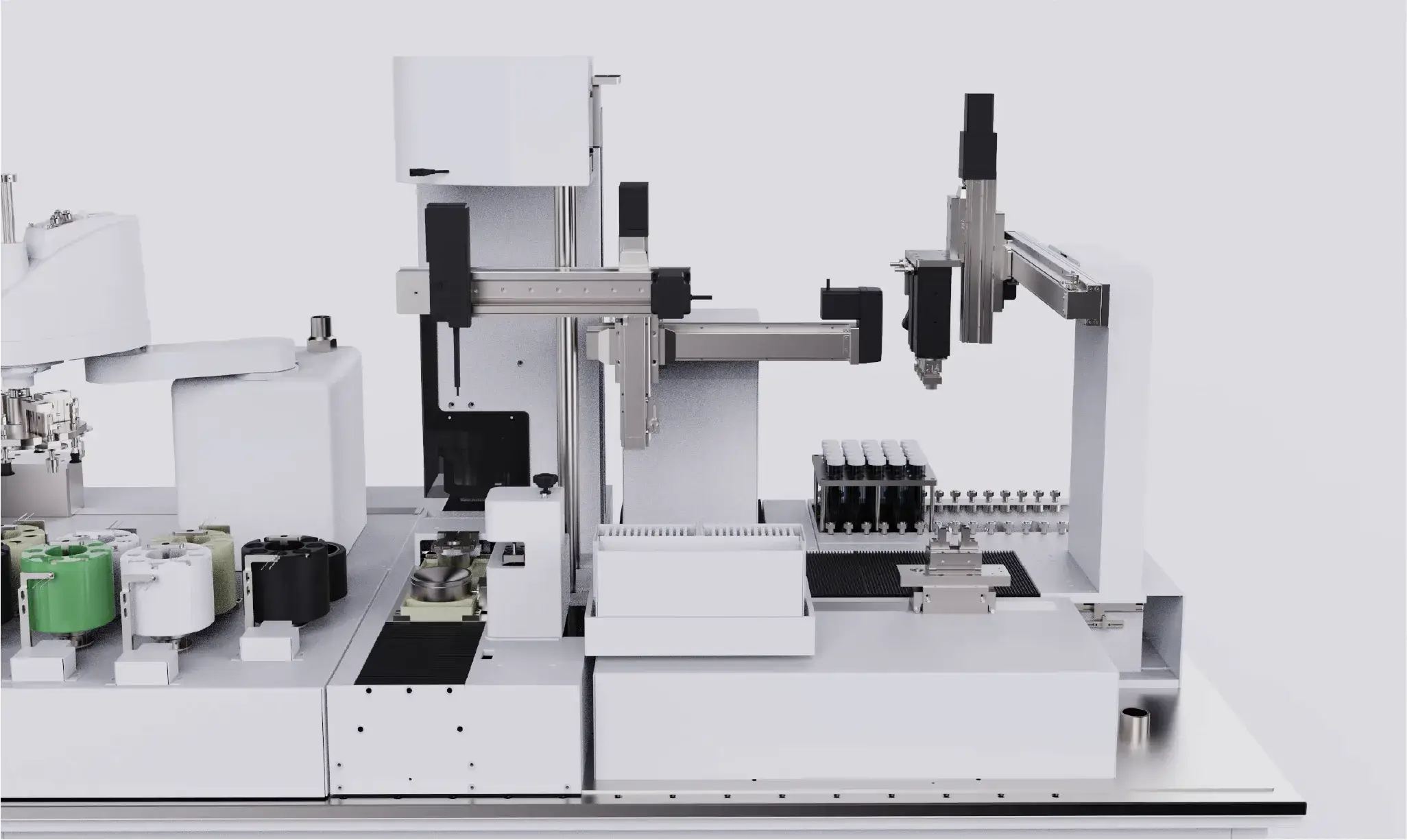

The Lab-scale Automated Coin Cell Assembly Machine(Compact Version) compatible with standard single-station, single-sided gloveboxes, integrates automatic electrolyte injection, automatic sealing, CCD positioning system, multi-station suction cups, enabling quick and convenient switching between coin cell assembly specifications. Assembly throughput is customizable from 1 to 10ea. It reduces labor costs, enhance assembly consistency, and minimizes repeated testing. Suitable for universities, research institutes requiring small-batch assembly of lithium/sodium-ion coin cells for testing purposes.

-

Description

-

Applications

-

Specifications

-

Download

The Significance of Coin Cell Assembly

In the preliminary stages of lithium battery R&D for novel materials and fabrication processes, coin cells serve as essentialplatforms for fundamental electrochemical validation, The precision in cell assembly directly impacts the reliability ofperformance metrics (e.g., capacity retention, cycle stability) and determines the bench-scale feasibility of materials forcommercial applications.

Customized Assembly throughput

Assembly Concentricity

Assembly Speed

Reduce the Assembly Time

System Features

-

Compact Design Integrates modules such as automatic electrolyte injection, automatic sealing, and a CCD vision system, etc.

-

Comprehensive Functionality Dimensions are engineered to perfectly fit single-workstation standard glovebox specifications.

-

High-speed Assembly Approximately 2 mins/cell

-

High-Throughput Assembly Up to 10 coin cells per batch, flexibly adapting to different needs.

-

Flexible Configuration Supports various common coin cell models such as CR2032, CR2025, CR2016, etc.

-

Wide range of cell types Capable of rapidly assembling half-cells, full-cells, and symmetric cells.

Rapid Assembly

High-Precision Assembly

Multi Material Suction Cups

Process Traceability

High-throughput Assembly

Automatic Sealing Module

Automatic Liquid Injection

Data Processing Software

Equipment Expansion

High-Throughput Automatic Electrolyte Switching System

Liquid Injection Module

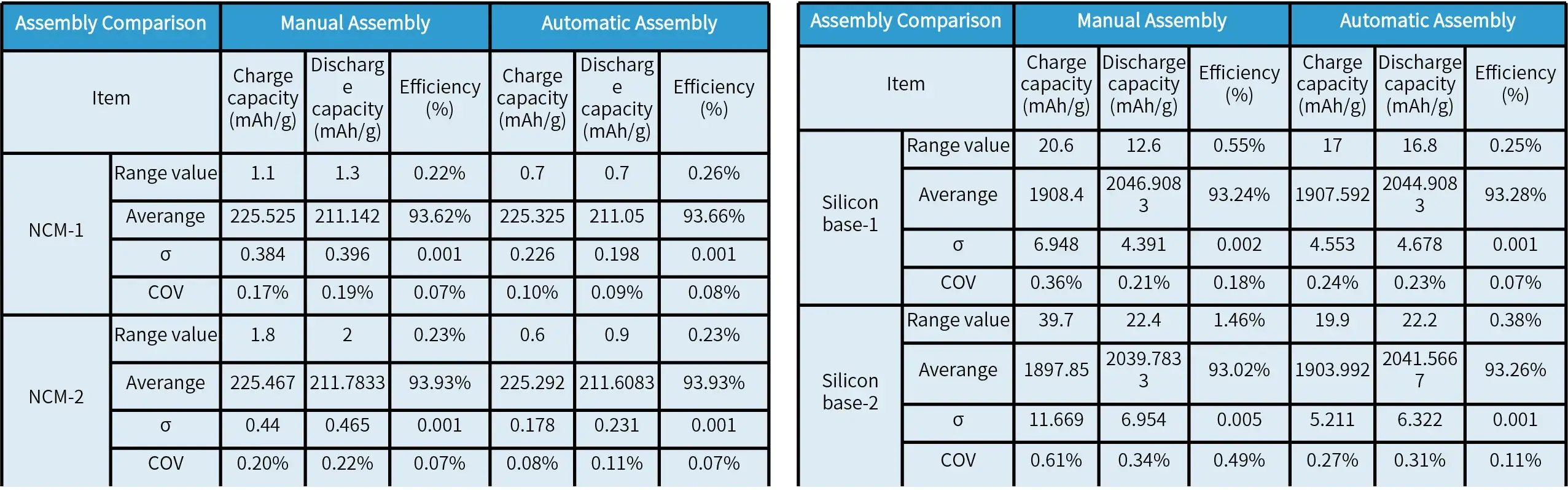

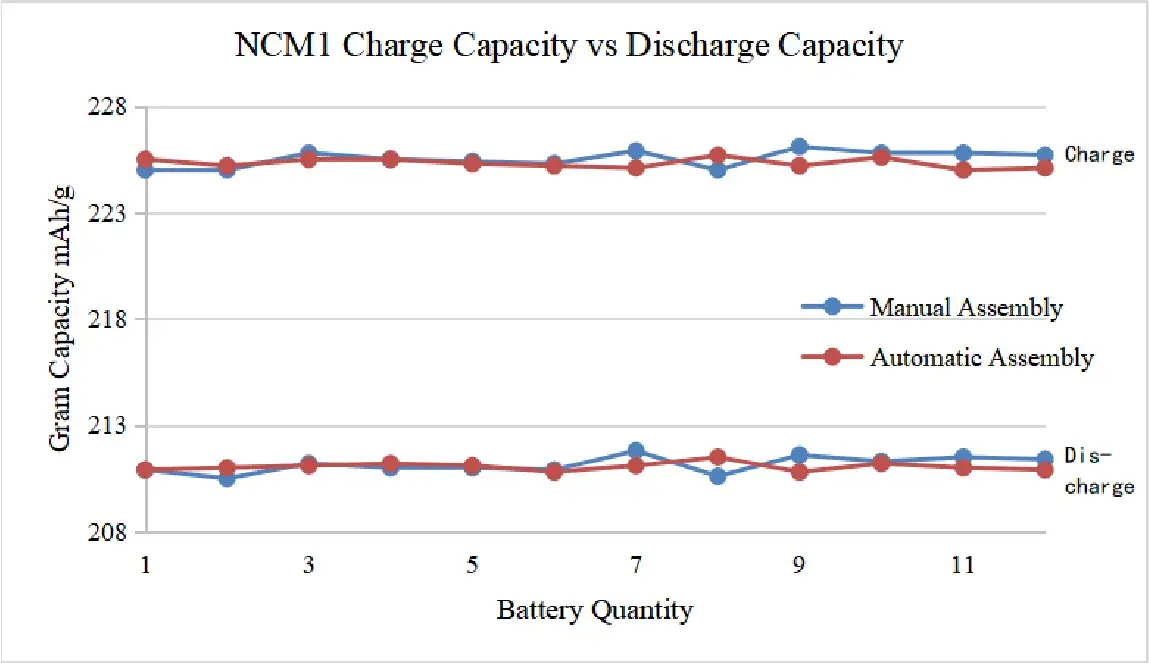

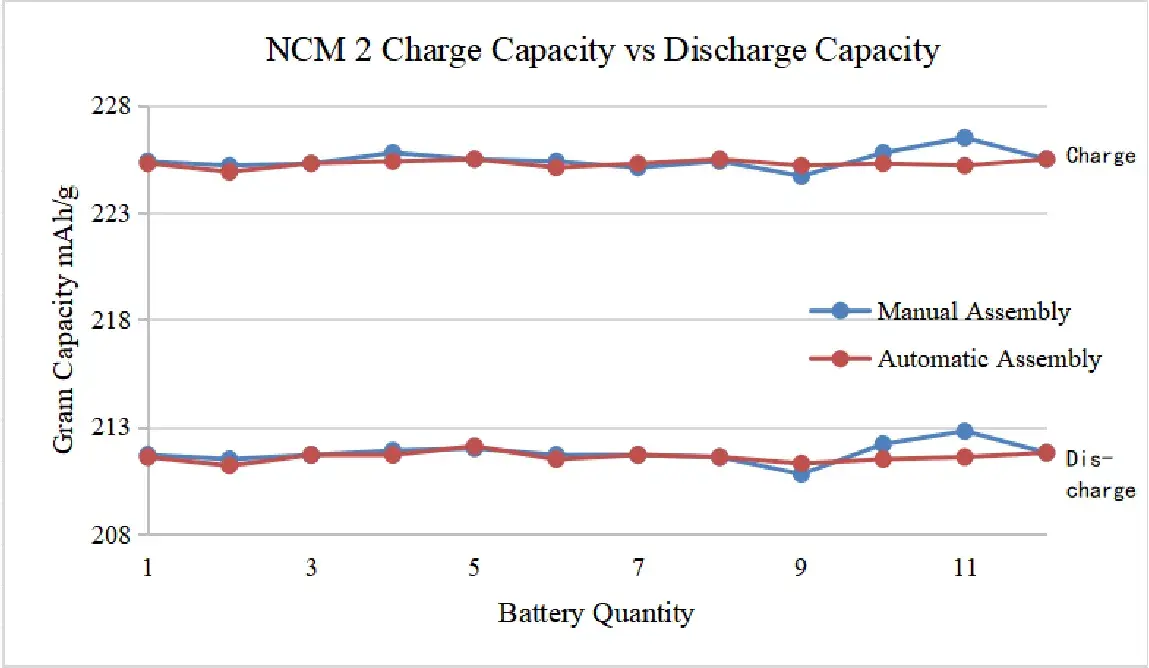

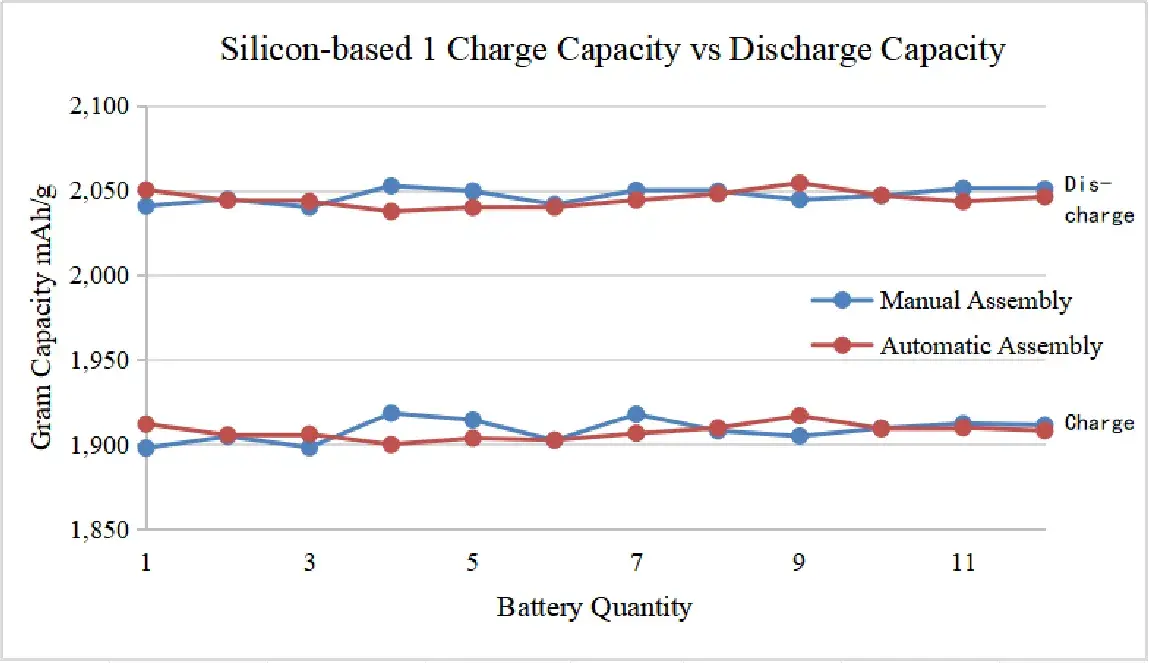

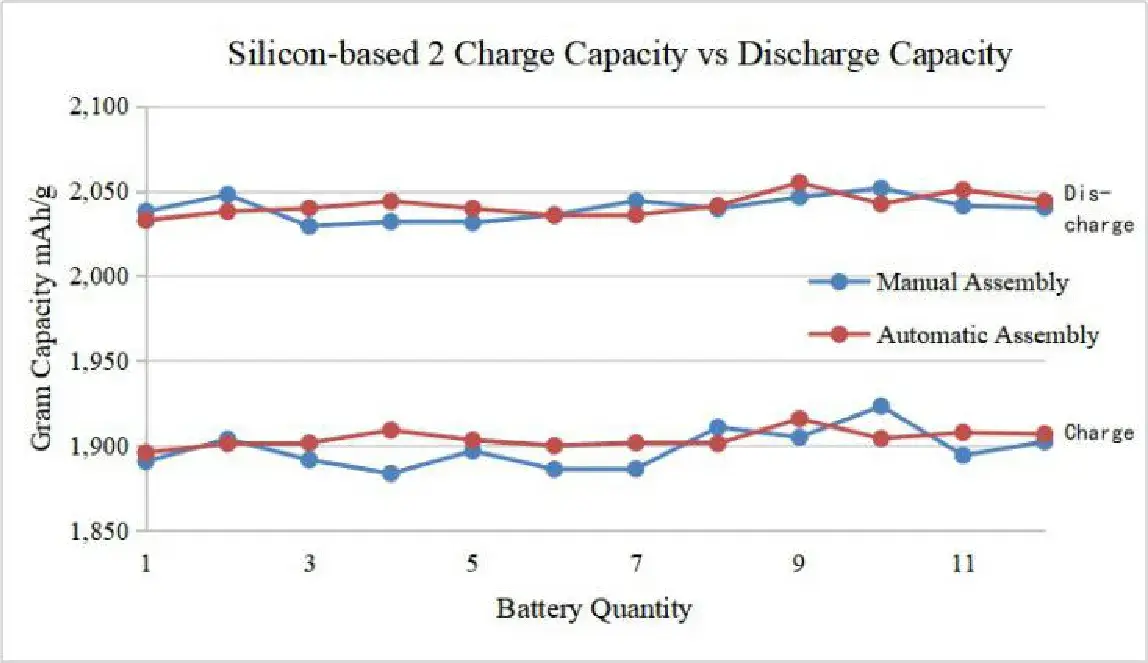

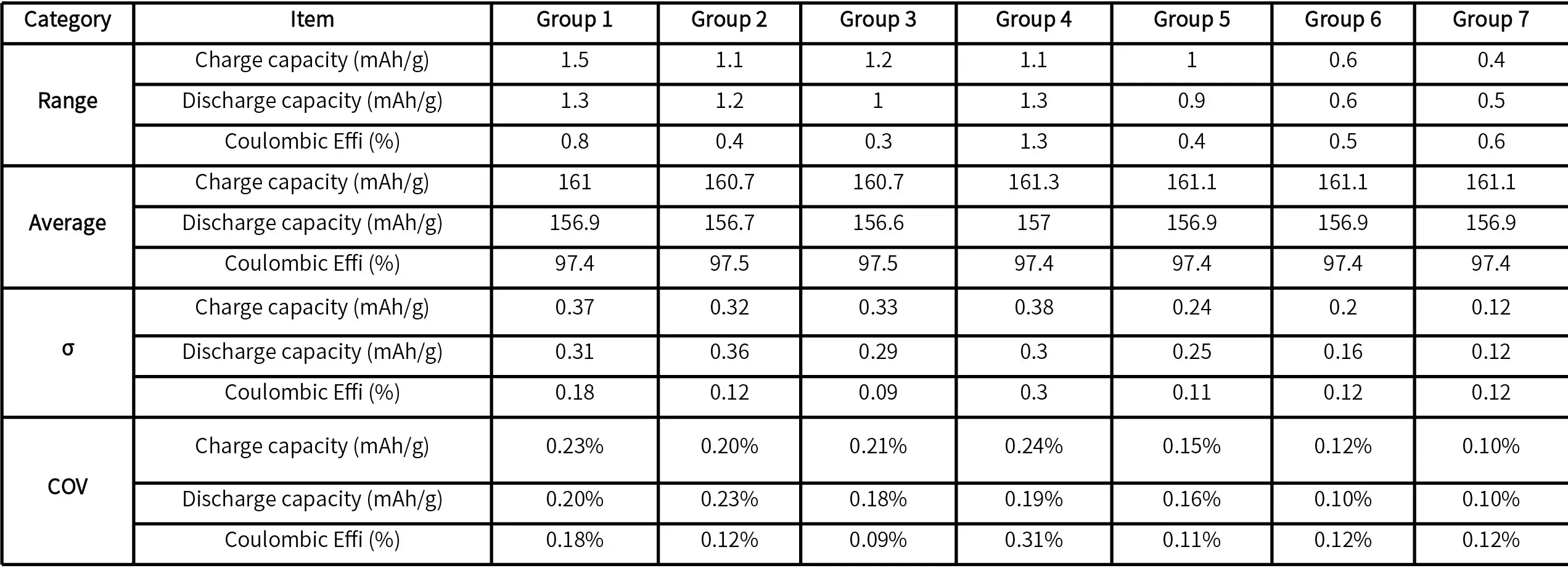

1. Case 1: Manual Assembly VS Auto Assembly

Conclusion: While the average specific capacity values obtained from automated and manual assembly methods were comparable for both material types, automated assembly demonstrated superior stability compared to manual assembly.

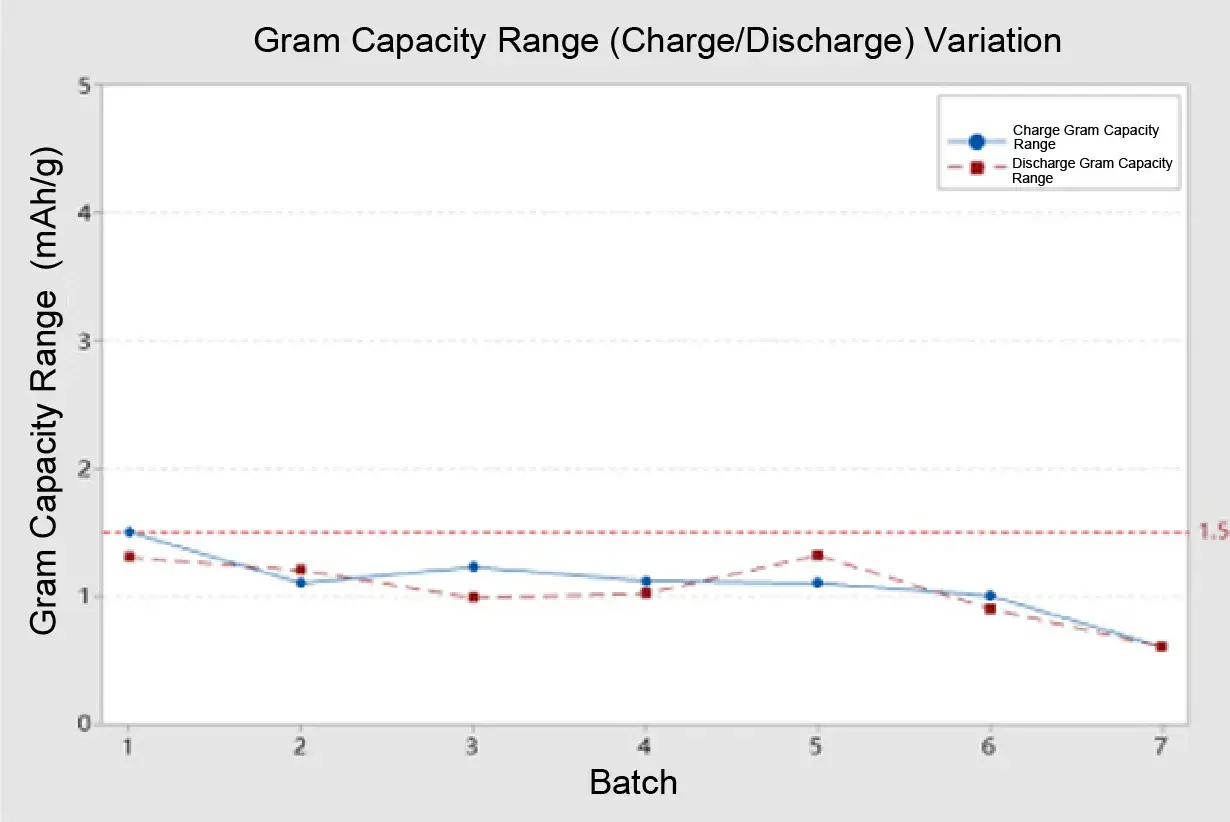

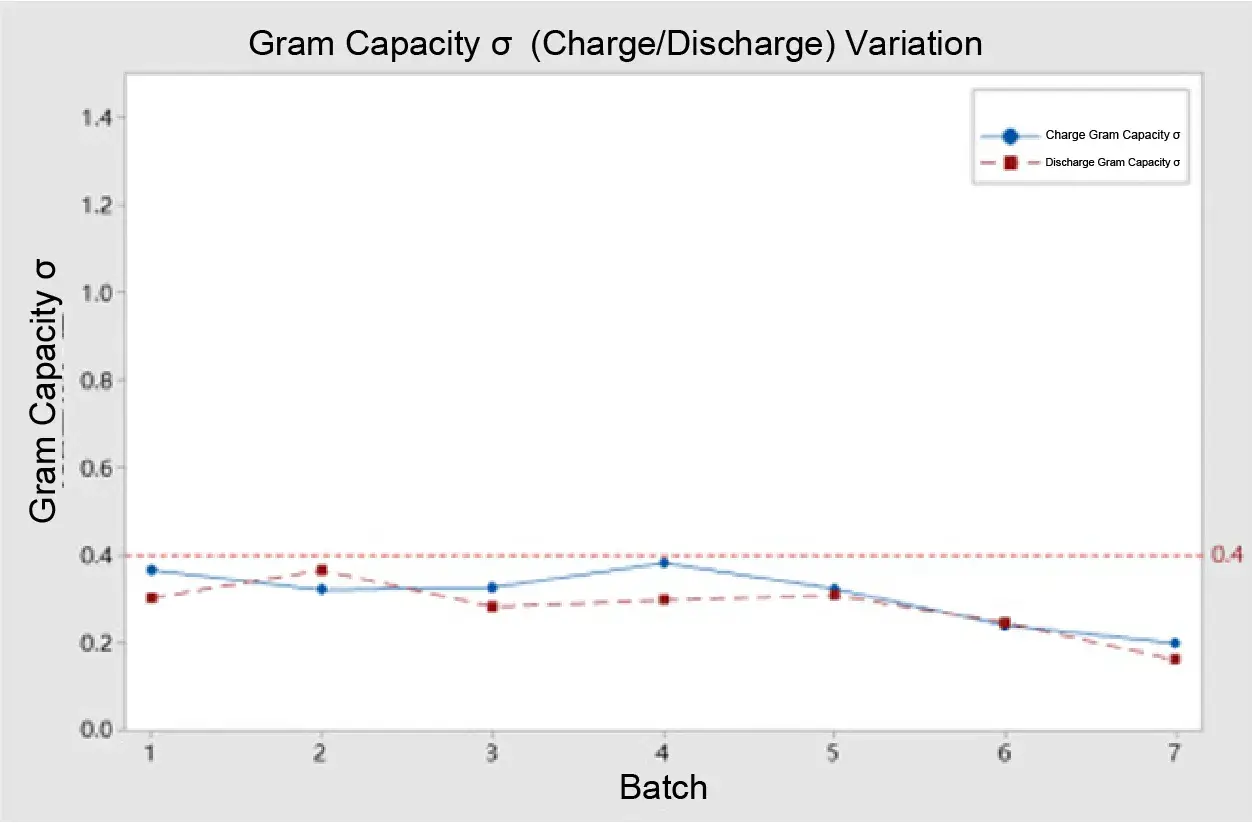

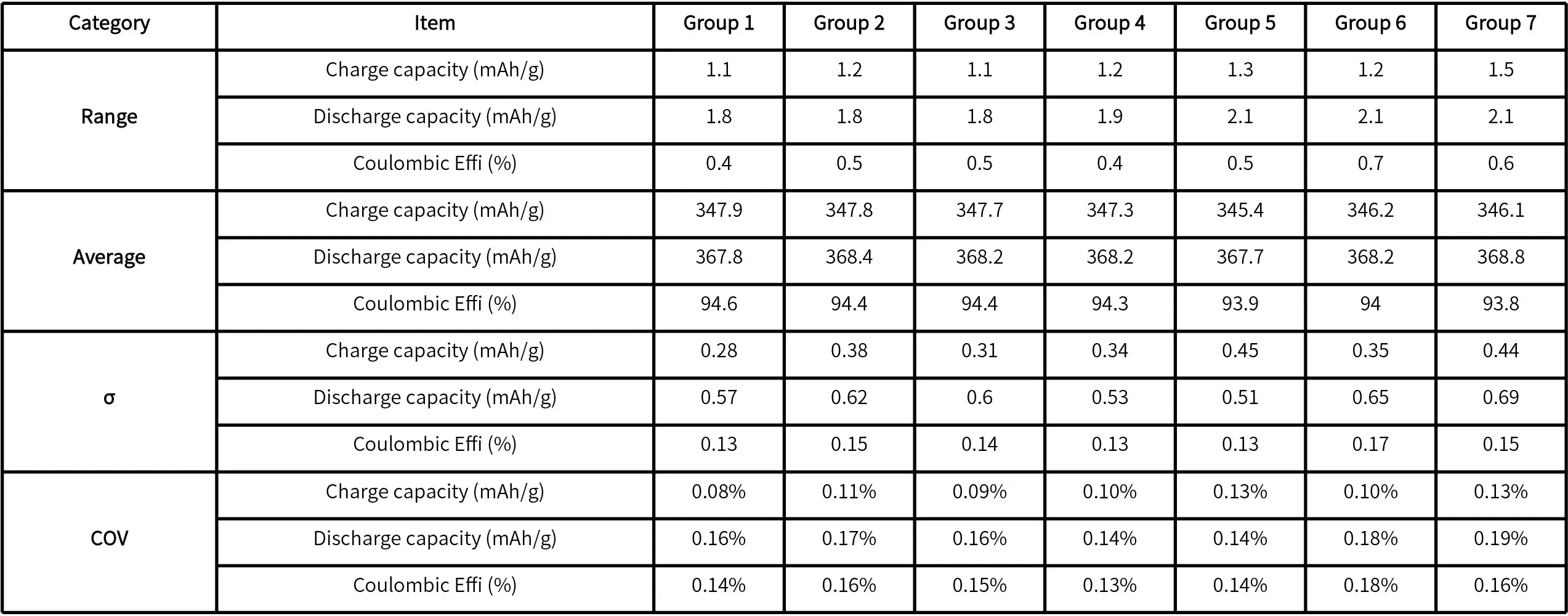

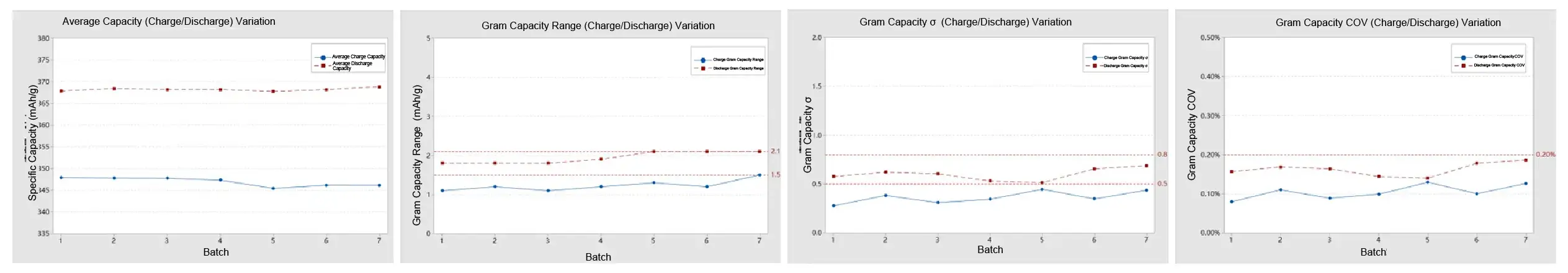

2. Case 2: Automatic Coin Cell Assembly of LFP Cathodes

Conclusion:

3. Case 3: Automatic Coin Cell Assembly of Graphite Anodes

Conclusion:

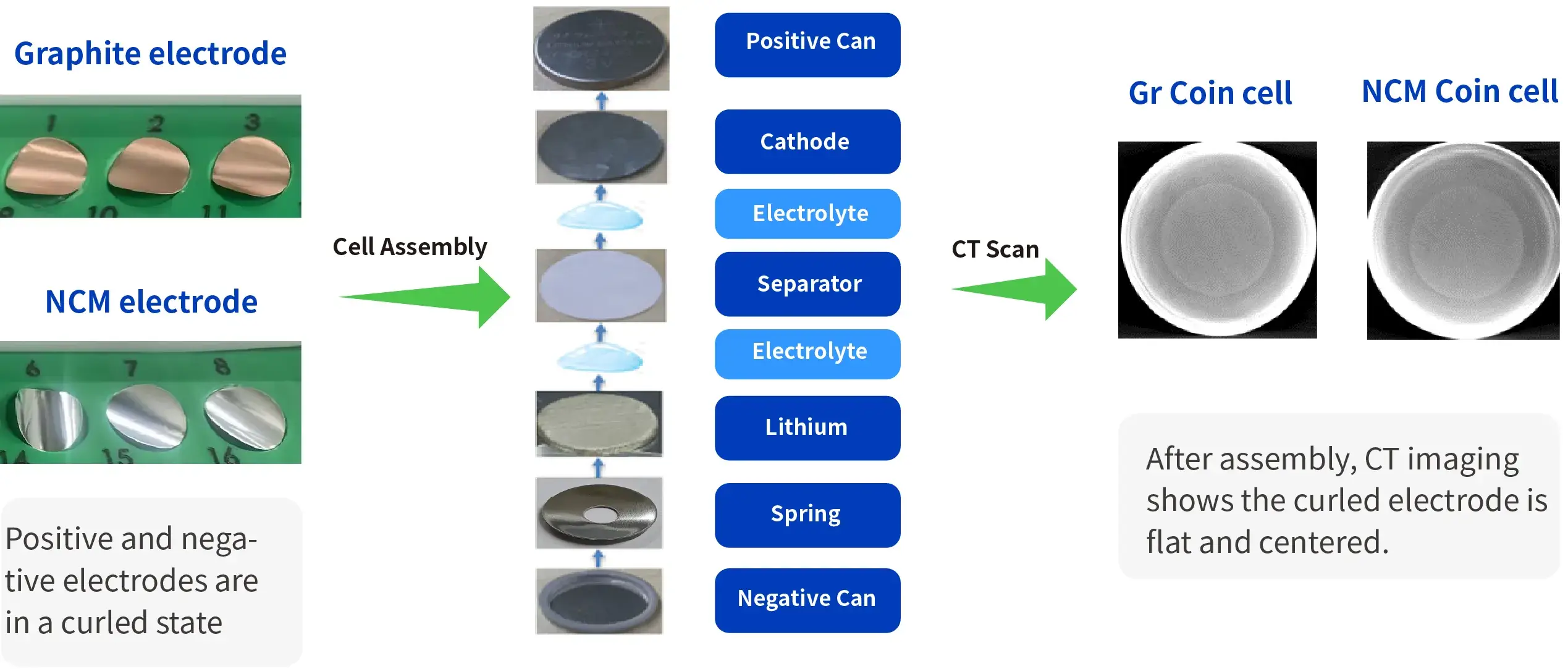

4. Case 4: Curling Issue of Single-Sided Electrodes after Calendering and Punching

Conclusion:

| Model | CAAS1000 |

|---|---|

| Photo |  |

| Assembly Concentricity | ±0.4mm |

| Assembly Accuracy | 2 min/ea |

| Suction Cup Positioning Accuracy | ±0.1mm |

| Electrolyte Injection Accuracy | ±2% |

| CCD Positioning Accuracy | ±0.05mm |

| Sealing Stroke Accuracy | ±0.02mm |

| Sealing Pressure Monitoring Accuracy | ±0.05%(Max Range: 2T) |

| Function | 1. Compatible with customer standard glove boxes. 2. Modular robotic arm. 3. Vision detection and positioning system. 4. Automatic sealing machine. 5. Automatic Electrolyte dispensing. |

IEST Coin Cell Automatic Assembly System(CAAS)

Next-Gen Coin Cell Assembly Solutions For Lab & Industrial-scale

Contact Us

Can’t find what you’re looking for? We provide customized solutions to meet your needs.